Introduction

Due to its remote location, Bendee Downs require an efficient transport network to link the site to developed areas and towns like Cunnamulla which is located 120 Km away. An efficient road network will provide easy transport and ensure a smooth movement of people between the site and the developed areas. The road will be designed to eliminate the possibilities of failure especially due to flooding during the rainy seasons. The design used for upgrading Murra Murra road is analyzed in this document with the most appropriate features being put into consideration. The design is strategic and ensures that the cultural relevance of some features in the areas such as the Nebine Creek is not distorted. The entire design process and all the features that are to be used on the road are as discussed in the following pages.

Design of the road

A road structure consists of sub-grade, sub-base, base and wearing surface. The structural element of the pavement is usually the foundation that is referred to as the sub-base and the base. A road can be classified as having medium to heavy traffic depending on the usage of the road. This classification forms the basis of the road design and the method of construction that would be suitable for the intensity of traffic. The design of Murra Murra road shall be cost effective and the future maintenance is expected to cost lower that the normal costing.

Sub-grade or Formation

This is usually referred to as the soil foundation or the surface of the natural ground in its final shape after completion of earthworks. The sub-grade forms a base on which the road surface rests upon. Therefore, it is important to note that if the sub grade or formation were to fail, then the whole road would fail. The sub grade should be prepared to resist the effects of maximum loading from traffic and adverse weather conditions.

Sub-base, foundation, soiling or bottoming

The main function of this layer would be to spread the traffic loads and weight of the base above. The sub base consists of the following element listed below.

- Hand packed big stones called rubble

- Bricks laid flat, or on the edge

- Over burnt brick bats that are rammed and are referred to as hardcore.

Base

The base course is the major structural component of a road and is composed of stone aggregate, granular material or road metal that is well consolidated. The main design considerations for the base include; thickness, stability, and resistance to weathering. The stability of the base depends on its thickness, whereby the thickness is mainly a function of strength of the sub-grade and the maximum wheel loads that are anticipated from the traffic intensity.

The Surfacing

This is the uppermost part of the road structure that helps in minimizing abrasion of the road and traffic. The surfacing material acts as cushion between the wheel and the base, and also reduces the adverse effects of climate. By acting as an impervious layer, it enables the road to shed storm water that would otherwise damage the road. The useful life of a road depends on the factors listed below which are very important during the design stage of the roads:

- The type of construction

- Intensity and nature of traffic

- Bearing capacity of the sub grade

- Climatic conditions

- Maintenance

- Road Design

Standard pavement structure that is employed in road design is composed of the base and sub-base. The base is made up of gravel such a murram while the sub-base is made up of natural material. The foundation to be used should be very stable in order to support the loading from traffic as usage begins.

Design Essentials

Drainage

Due to the effects of water on the road’s operation and maintenance, effective methods should be adopted to eliminate water from the road. When the percentage of water gets higher in the base material, there is an overall reduction in the strength and stability of the road. Potholes may form on the surface of a road when too much water remains on the paved area for longer periods without elimination. These results due to the effect of pressure build up and release on an already weakened surface. Where the road drainage is very poor the stagnant water has a negative effect on the pavement edges such as cracking. Therefore, for a road to be safe, efficient, and long lasting, the drainage should be designed to ensure water on the carriage way is redirected into drainage channels.

Built on a Firm Foundation

The road should be established on a firm foundation which can safely receive all the loading transferred to it from road traffic. A firm foundation shall help in providing a durable road with less maintenance requirements in the long term period.

Sub-grade Formation

The soil that is used in the sub-grade should be strong enough to carry the loading and transmit it without failure. The strength is achieved by compaction of the soil in layers to attain the maximum density that will serve the purpose effectively. This results in stable soils which will not fail easily on loading.

Accommodate Traffic

Roads should be constructed with the correct expected traffic type and density in mind. This will ensure that the road is not overloaded due to presence of denser traffic. Accuracy during the design process therefore, ensures that the road continues to operate without failing for longer periods of time.

Maintenance

In order to have a long term and efficient road performance, proper maintenance activities should be practiced. The maintenance practices that are carried out on roads are administered in the manner that is described below for effective results.

- Drainage: – inspection of the road elements should be done and corrective measures taken appropriately.

- Surface of the road: – Constant repair of worn out surface should be done to prevent further wearing out of affected road sections.

- Road sides: – Vegetation along the side of roads should be trimmed to ensure visibility on the road is not compromised.

Types of roads

Flexible pavement

This type of road design consists of a number of layers of various materials which distribute the loads applied on it to the sub-grade material without any permanent deformation.

Rigid pavement

This design consists of a concrete slab resting on a thin granular base that prevents water from accumulating by having a natural gradient incorporated in the concrete structure (Lewis, 2009). In this design for Murra Murra road however, rigid pavement design shall be the most efficient. Therefore, a rigid pavement road shall be used for the design. This will provide a long lasting solution to the transport menace in the region.

Road works

Road works are executed in two procedures which include earthworks and pavement construction as described below. The construction of Murra Murra road shall be designed to provide effective and long lasting network to link Bendee Downs to the more developed areas and towns that are close to it. This will ensure that the main intension for development of this rural area is achieved. The expected increased mobility due to the road upgrade will enable many people to travel to Bendee Downs thereby triggering development in the region.

Earthworks

This is concerned with preparation of soil to bring it to the correct level, gradient, profile, and strength. The finished level of earthworks is called the formation level and the soil below it is called the sub-grade material.

Pavement construction

This involves backfilling the cut ground section with suitable materials which are then compacted until the required formation level is achieved.

Factors considered in road design

- Strength requirement – roads for heavy commercial vehicles need to have higher strength than those for lightweight vehicles.

- Users of the road – the user of the roads define the use: whether heavy commercial or medium weight vehicles.

- Durability – different materials have different lifetime and hence durability is a core consideration.

- Cost – different types of roads have different cost implication.

Shoulders and drainage

- Storm water from developed sites should not be permitted to drain onto streets or abutting property.

- The soil throughout the site is highly pervious and capable of absorbing storm water. Shoulders of drives and parking areas may be pitched away from the pavements to eliminate storm water stagnation.

- Shoulders shall be at least 6 feet wide before sloping to existing grade.

- The side slopes of non-cohesive soils are governed by natural angle of repose of the natural material.

- Typical slopes may range from 1 in 4 to 1 in 2 but must be determined from tests in the lab. Compressible soil must be removed and stabilized.

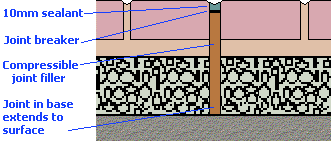

Construction of rigid pavement (Murra Murra)

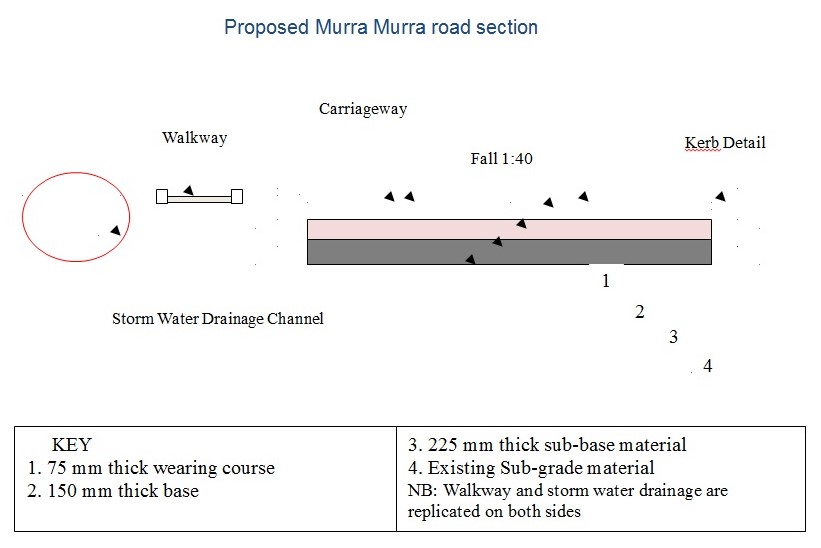

The diagram below shows the section through the proposed upgrade of the earth Murra Murra road. The details show clearly the design approach that has been used to come up with the idea and all the individual elements are clearly indicated.

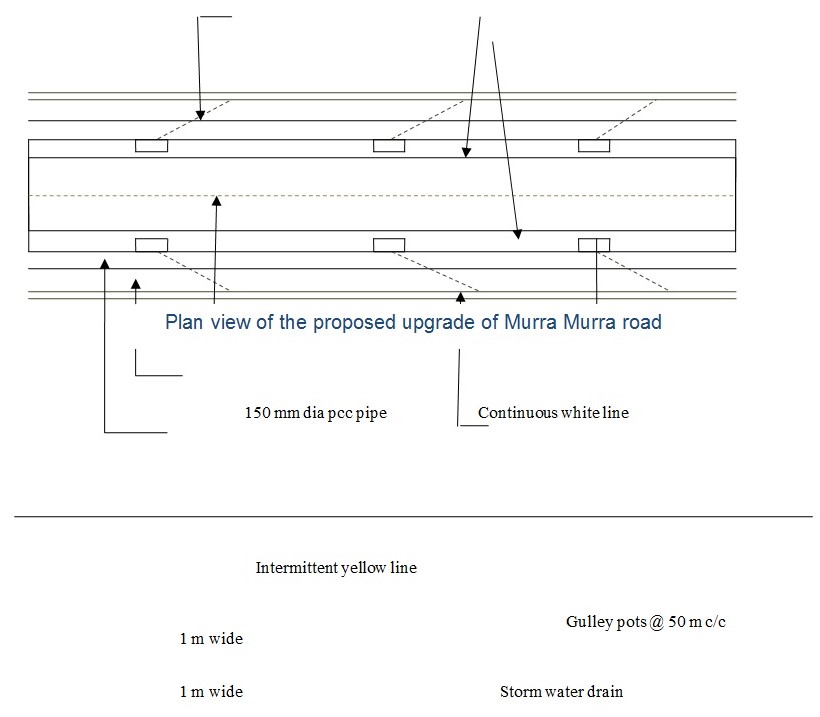

The figure below shows the plan view of the proposed Murra Murra road.

The material to be used as the wearing road surface are 200x125x65mm Medium duty concrete paving blocks of minimum crushing strength 45 n/mm2 .

These materials have been chosen as the most preferred due to a number of advantages some of which are listed below.

- This is due to the fact that paving blocks can last up to 20years without rehabilitation when correctly laid.

- They also have a high aesthetic value.

- Maintenance and repair is faster and easier as compared to other elements.

Bedding layer

The bedding material should be stiff, but retain its plasticity. The mortar ratio shown below shall be used for the bedding layer to ensure stability.

sand (3) + lime (1/4) +  cement (1)

cement (1)

Formation

Formation involves processes like scarification of existing surface and removal of loose materials. Soft material/ rocks are cart away. Filling materials are then provided, laid in layers, and compacted. Compaction is mainly by use of mechanical roller.

Sub-base, Base, and Wearing Courses

The sub-base shall be composed of murram, gravel or crusher run material in accordance to specifications and requirements. The base course is usually composed of asphalt or bitumen and may include crusher run base course material. Finally, the wearing course shall consist of a bituminous primer laid and compacted to specifications as shown in the road details and section profile. Other features which come with the specifications are as described below.

- 250 x 125mm precast concrete kerbs on 100mm grade 15 concrete bed and haunch as described.

- Trapped road gullies complete with 150mm diameter precast concrete pipe.

- Precast concrete quadrants at kerb junctions.

- Street lighting poles complete with cabling, lanterns, and control gear fixed in class 15 concrete foundation or as approved.

- Culverts according to the conditions on site.

- Head walls.

- Manholes as approved.

- Side slabs to open channel drains.

There is no expectation of heavy traffic to the eco-tourism attraction as mainly human transport is expected to be more prevalent especially since it is still in the implementation stages. The carriageway is designed as a two way system and constructed using asphalt. Parking areas that shall serve the road especially in bus stations and petroleum stations shall be constructed using concrete products such as cabbro blocks. The design of asphalt road being the major type of road will be based on California bearing ratio (CBR) and the equivalent standard axle (ESA) method taken from roads design manual as shown in the excerpt below.

- CBR = 10 – 18 % designed with 12

- ESA = 10 – 25 x 106 designed with 15

The site has a mixture of murram soil, red volcanic soil and scattered rock chippings along the Murra Murra road. We shall therefore design a road with 225mm of cement or lime improved material for sub-base material, a 150mm cement stabilized gravel for the base and a 75 mm wearing course of AC type 5. The road reserve is about 25M comprising of 2 lanes 3.25M wide each, 1.2m foot path on either side of the road storm water drains on either side of the roads and a way leave for other services like water lines, drainage pipes, and electric cables. The footpath and carriageway shall be separated by a kerb on either side of the road to prevent accidents and direct runoff to the storm water drain.

The carriageway shall have a fall of 1:40 on one side to facilitate drainage directing the storm water to an open drain on one side through 150mm drain pipes connected from I M deep road gully to facilitate collection of silt and any other solid waste being carried by water. The gullys will be constructed at intervals of 50M. Much of the truncation will be at 900 and therefore the truncation radius will be based on the half, half (½ / ½) method. That means that it will be formed by ½ the widths of the adjoining roads.

Kerbs

Installation of kerbs along the Murra Murra road will provide an attractive appearance on completion and many other functions as described below. The kerbs are provided along the carriageway on Murra Murra road to protect the edges of the carriageway by preventing spreading which may lead to loss of structural integrity. Another important function of the kerbs is the provision of a barrier clearly indicating the separation between the road traffic and pedestrians. This helps in reducing the number of potential accidents which might possibly occur if the barrier lacks. The kerbs may also act as a way of preventing skidding vehicles from leaving the carriageway and pose safety risks to pedestrians. During the rainy season, the kerbs form a channel within which rain water can be effectively drained.

Storm water drainage

Storm water is the water from rain that accumulates as surface run-off and drains into the drainage channels. It is essential to drain such water to ensure that paved areas are not flooded. Flooding can also be risky as heavy flows may lead to destruction of paved areas and may sweep off the roads when its actions are severe. The factors which are considered when designing for storm water drainage channels are as described below.

- The area of catchment is a major determinant and greatly influences the design and capacity of storm water drainage. For instance large catchment areas mean an increased amount of rain water will flow into the drainage channels. Therefore, the drainage channels in such cases shall be constructed large wide enough so as to accommodate the large quantities of water without causing damages to the sides.

- Impermeability factor also affects the size of drainage channels, such that greater impermeability causes less water to be lost through infiltration. The relationship between impermeability of the surface is directly proportional.

- Rainfall intensity. Areas with high rainfall receive higher rainfall capacity which has to be effectively accounted for in the design of the channels. Therefore, higher rainfall intensity means that the drainage channel shall be designed to carry the more water safely. This is therefore a direct relationship that exists.

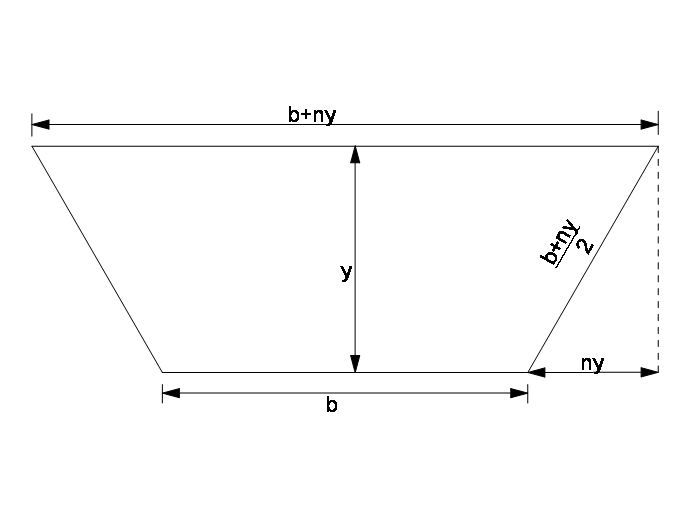

The project will adopt an inverted block drain mode to drain storm water. We shall use open channel drainage method that will be trapezoidal in shape and will include an invert block drain (IBD) and side slabs. This will give us maximum discharge for a given amount of excavation and therefore maintain the safety standards. Since the area within the scheme slopes gently, the problem emanating from drainage of storm water is not a major problem in the design.

The incorporated open drain channels along the road with adequate drain and cross culverts will facilitate the flow of storm water along the drainage into the river. The lining of the open drain channels is a pre-cast concrete slab with stone pitching where there is high soil erosion. The sizes of the culverts are 900 mm in diameter to provide enough space for maintenance and inspection. Storm water is to be drained through steel coved drain channels of invert block drain from precast concrete. This system has many advantages which include the following listed.

- It has easier maintenance requirements.

- Can handle surcharge of flow which is beyond capacity unlike in closed drainage.

- Can be varied in terms of depth and width to cater for surcharge.

The amount of storm water in a scheme is dependent on several factors some of which are listed below. These factors should be effectively employed so that the drainage channels are not either overdesigned or under designed. Under designing can lead to drainage inadequacies which may cause failure of the structure as a result of flooding in the channels.

- Area of surface which varies directly to the amount of water flowing into drains.

- Type of surface which is a measure of the permeability.

- Topography of the surface.

- Intensity of the rainfall which means direct relationship.

- Seasonal condition i.e. relative humidity in the air which affects the amount of rainfall that is received in a particular day.

- Evaporation rates where high evaporation leads to higher rainfall received.

The surcharge is later directed into open channels criss-crossing the fairways which double up to provide good appearance and hazards to the play. The water is finally collected in ponds strategically positioned in the course.

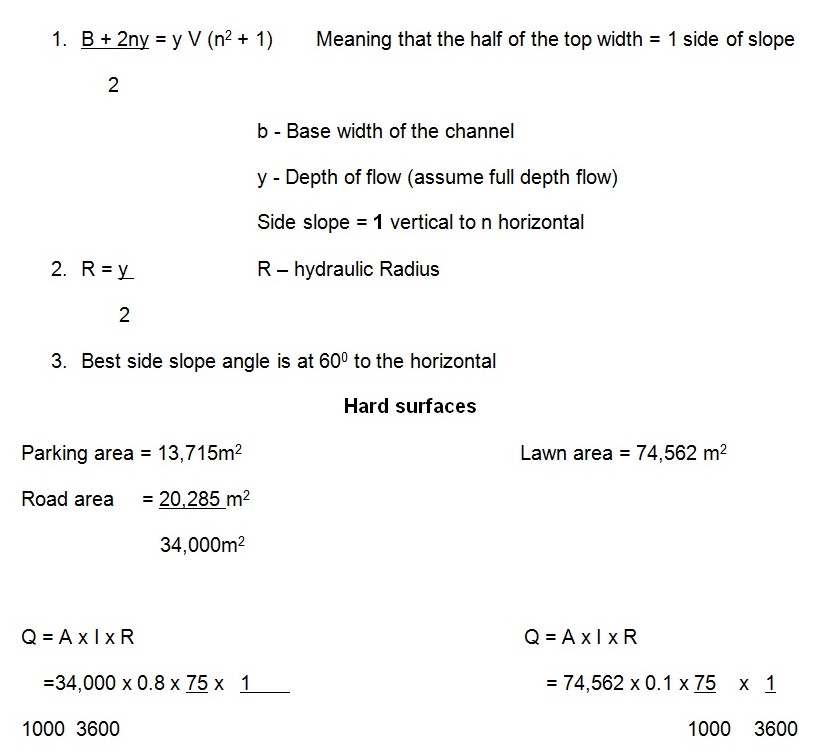

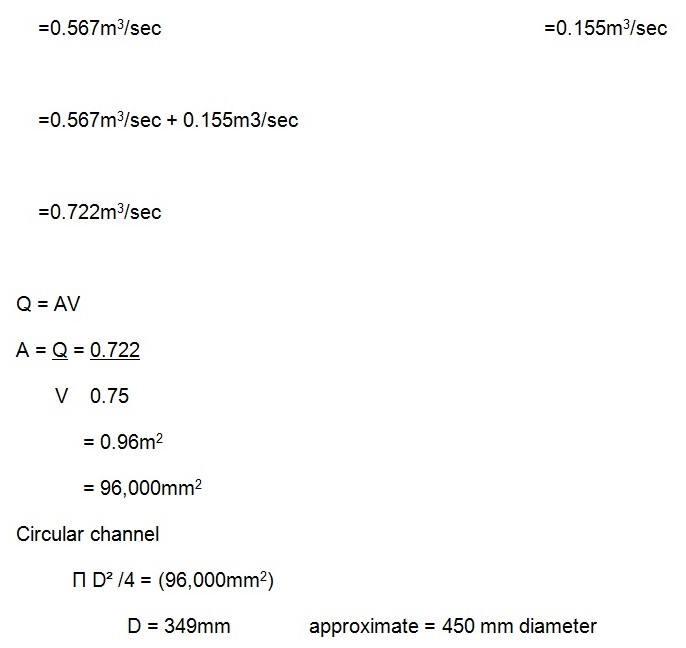

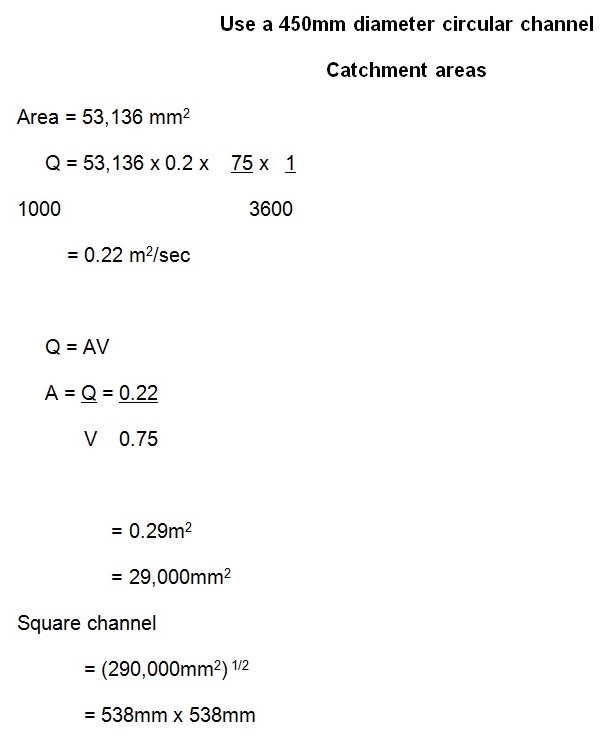

For the trapezoidal section shown below, the calculations shall be done as step by step as shown in the following design calculations.

Part B: Long-Term Road Maintenance Plan

The maintenance of roads is done to ensure that roads remain functional for long periods of time and that any faults are corrected. The maintenance plan of the road is done under five main categories which include: drainage, surface maintenance, cut and fills slopes, erosion control, and vegetation control (Anonymous, 2000). Any maintenance that is to be done on the roads should do so under the above categories so that efficiency may be obtained. Failure to adhere to the requirements of road maintenance shall mean the performance of the roads shall be compromised. This may occur due to the fact that roads may be filled with mud deposits, erosion on road sides, and excessive growth of adjacent bushes among other problems. The overall effect therefore shall be hazardous to the users of the roads and may be a great drawback. For our case, there is a detailed maintenance plan which shall be used to ensure that the Murra Murra road, foot paths, walk ways, and other connections in Bendee Downs are appropriately attended to. The whole plan is as detailed below under the above listed categories.

Drainage Maintenance

Under this category, we shall ensure the effective maintenance of the road drainage which includes catch basins, ditches, and culverts. These elements in a road are of a high importance an effective maintenance should be done to ensure a long-term and smooth operation of such road. As a routine maintenance, there should be a series of culvert cleaning especially during the summer season where corrective measures may also be done when identified. This will ensure the roads remain in a perfect operation and no hazards are created. Inspections should also be conducted to check the conditions of the culverts in seasons where the rainfall is very high. The main reason for carrying out this operation is to ensure that the culverts are not clogged by debris and that they remain fully functional. Cleaning should be done and clogging particles removed where such a condition occurs. This ensures that no road damages results due to the clogging since the overall expenses on road repairs is usually very high.

Where cleaning is done, the sediments and floating materials should be removed and disposed off the road side in ways that shall prevent such materials from getting back into the catch basin. This should therefore keep the catch basin clean and maximum flow of water is possible during the high rains which could cause flooding. Culverts on the other hand should be cleaned and clogging materials removed and damped away. In case of damaged ends of culverts, the problem shall be corrected by an appropriate means such as fitting the outlets with a downspout.

The road side ditches should also be maintained so that maximum flow of water from surface run-off can be effectively controlled. Inspections should be carried out on the ditches especially during seasons of high rainfall and thoroughly cleaned. Where erosion of such ditches is noticed, the ditches should be covered using riprap or additional culverts are added accordingly. However, when carrying out maintenance on the ditches, proper ways should be used to ensure that this is not done excessively. Grass and vegetation should also be maintained at realistic levels to ensure since they are beneficial in many ways such as filtering out of sediment. Carrying out all these operations in the right way as described shall ensure safety of the road. Below are the ways in which specific maintenance practices shall be carried out on drainage components to ensure an effective drainage exists.

Gully cleansing

Gully cleansing is carried out so as to ensure there is very minimal or no flooding on the roads which may render it impassable during the rainy season. The cleansing technique works by allowing surface water to flow freely into the drainage system via well drained gullies and gully gratings. The maintenance program in this case requires that there shall be a routine cleansing of all gully pots which are located on the Murra Murra road. This maintenance will ensure that all risks associated with excessive flooding are eliminated from the whole system. The activity should be carried out at least once per annum the frequency can be increased during the rainy season so that the possibility of flooding is significantly reduced.

Gully cleansing is done by cleaning the different components so that they can work in coordination to enhance maximum flow of the water. For instance, the cleaning process starts with the gully rating where the debris and sediments are removed from the gulley pot. The second procedure involves ensuring that there exist a maximum flow rate along the channels which is effectively checked by filling the pot with water and releasing it. The efficiency by which the water is released into the into the road’s drain is monitored and used to rate the results of the cleansing. Where the flow in the drain happens to show an inadequacy, an appropriate means is used to remove the blockage from the system. This may be effectively achieved by using the rodding and jetting process of unblocking. Faulty gullies on the other hand, shall be inspected and all information supplied to the concerned engineers for rectifications and repair. By carrying out all these procedures effective flow of water shall be achieved thereby reducing the chances of flooding that may lead to heavy damages to the road system.

Road Surface

The road surface is critical part of the road since it determines many actions and the functionality of the road such as driving speeds and comfort (Lewis, 2009). However, grading of such surfaces should be done when there is an extreme need for it such as in cases where the stable running surface is compromised greatly. This should be done in such a way as to ensure costs are kept as low as possible while making a good grade at the same time. This activity should be done cautiously since excessive grading leads to an increased rate of rock ware which leads to unnecessary erosion on earth roads. The tarmac road and carriage way shall be maintained to ensure maximum operation during the dry and rainy periods. Some of the maintenance practices that are to be carried out shall be in accordance to the part of the road that needs the practice. Below are examples that explain how maintenance under this category shall be done.

Carriage way markings

Road markings should be provided on the carriageway to provide an efficient way that will ensure ease of movement along the road. The road markings should be clear and be able to operate in all types of weather conditions without fast fading. Such markings will help in providing clear directions to the pedestrians and motorists thereby ensuring a safe and efficient road network. Inspections shall be conducted on a cyclic basis and all the road markings replaced on a yearly basis. This allows the road users to have a maintained and efficient road system after such services have been completed. The road markings that shall be used must follow all the traffic rules and regulations to allow perfect relations between the motorists and pedestrians.

Surface Dressing

This maintenance treatment is usually applied to carriage ways and footways so that a quick solution to road wear is obtained. This maintenance practice is usually very cost effective and also an efficient way of making the existing road’s surface better. It is done by spreading a bituminous film on the road’s surface which is then covered in stone chippings. There are many advantages which come with surface dressing. As an example, skid resistance of the road surface is improved depending on the polished stone value of the aggregate used. The layer formed by bitumen also forms a water tight barrier that keeps surface water out and prevents deterioration of the surface (Lewis, 2009). A newly dressed road surface has an improved appearance since patches and joints are covered in a uniform color and texture.

Surface dressing shall be administered annually where a program of the works will be prepared and contracted for work to be executed during spring. Surveys will be carried out to locate portions which have skid resistance deficiency and these areas shall be corrected accordingly. Portions having the highest risks of wear shall be repaired in order of priority in the next surface dressing programme. These services will ensure the peak operation of the road and reduce cases of accidents in the region due to skidding effects. This maintenance practice should be done in accordance to the requirements that are provided in the codes of practice.

High-friction surfacing

All pedestrian crossings and other road areas that require high skid resistance shall be maintained in a thin layer of veneer surfacing material. This shall also be used where there are sharp bends, signal controlled junctions, and in roundabouts where emergency breaking may be required. This maintenance practice will assist as much as possible to reduce possible accidents among motorists, pedestrian and animals using the finished road. All the works shall be done in accordance with the requirements that have been provided in the codes of practice for roads.

Surfacing materials

The surfacing materials to be used should be economical and must be durable to reduce the rate of re-surfacing the roads. This will help in providing a long-term efficient maintenance to all the roads available. During the long-term maintenance plans, the use of recycled materials and sustainable products shall be employed to make it a cost effective solution. The construction works under this category shall be carried out in accordance with all the requirements in the codes of practice.

Road crossings

Since the road is located in the rural areas, there should be an adequate way of ensuring they understand the road signs that are available in the system. This is due to the fact that people in risky areas may tend to cross the road without knowing the dangers that they are exposed to. Another circumstance occurs where local people with large herds of cattle and other domesticated animals are in existence and would cross the road from time to time. This may pose a great danger to people’s lives as well as to their animals. Therefore, an adequate crossing facility should be provided to counteract such problems. There are up to four types of pedestrian crossings which are be used but due to the rural location of this road in question, zebra crossings may be adequate for the purpose. The advantage of using zebra a crossing is that it is relatively of low cost installation yet it works effectively. Along the Murra Murra road, zebra crossings shall be used where there is a likely danger to the people crossing the road at such points. Where there are many animal herds, such crossings will be provided to ensure that the stock owners are safe with their animals. Maintenance of these crossings will depend on the road traffic in any particular year. However the crossings should be redone at least twice every year to ensure perfect appearance and its visibility. The crossings will ensure a perfect solution to traffic dangers and maintain a significant level of safety to the local population.

Road signs

Road signs are classified into two categories which include those that govern pedestrians and those which help to organize traffic. The signs used are standard so that it is easier to internalize and effectively respond to them. Signs that are intended for pedestrians are installed to fulfill a number of objectives such as to direct them effectively on the roads. Other signs may be used to warn pedestrians of dangers that may exist on the road and may be of a temporary or permanent nature. Pedestrians can also be informed and instructed about issues on statutory prohibition. Where permanent sign posts are used, installations shall be done to ensure that structural stability is attained. Traffic signs which are installed on the road will aid in the safe and effective movement of along the road network. Most signs shall be installed to warn motorists against dangers which may be present at different spots on the road. The signs can also be used to provide information and instruction to motorists on statutory prohibitions along the road. All road signs should be clear, structurally fit, and provided for the right function and in the right time. This increases greatly the functionality of the transport system by easing movement. The sign posts should be inspected at different times in a year to check for missing, destroyed, and required information signs. Damaged and destroyed road signs shall be replaced depending on the degree of damage while others may just be repaired and repainted. This will provide an easy and faster solution to communication breakages between the motorists and the pedestrians for their own safety.

Footways

Pedestrians should be provided with safe walking lanes along the road to ensure efficient movement and limited interference with motorists. This also encourages safety practices among the users and the overall effect is an accident free system on the roads. In order for this to be achieved, the fabric of the road should be well maintained as well as the footpath. Depending on the current trends on the frequency of use, the footways shall be inspected on a cyclic basis and all the maintenance works implemented. The footways along the road shall be shall be surfaced with black bitumen macadam to provide a durable and long lasting finish. This surface finish requires minimum maintenance practices over a long period of time which makes it economical in the long run (“Pothole,” 2010). However, inspections shall still be conducted on a yearly basis to check if the footpaths are in their perfect working condition. In case any defaults are identified on the footpaths, minor improvements and repair shall be done to ensure efficiency is not reduced. In case of major destruction in situations like flooding, fresh resurfacing may be done and according to the requirements.

Cut and Fill Slopes

Slopes where cutting and filling has been done shall be effectively compacted to ensure that the soil matter does not fall off into the carriageway. After appropriate compaction has been done, the grass seeding can be applied to these areas. Grass will ensure that the soil covered and therefore surface floor in such areas will not affect the road system. Inspections will be carried on a yearly basis and corrective measures taken to prevent already damaged parts do not pose safety risks to the road users. Perfect solutions in road maintenance will lead to effective and safe movement of people from the urban to rural Bendee Downs and vice versa.

Erosion Control

Soil erosion along the road reserve can lead to a lot of menace. This may be even worse during the rainy seasons where a lot of water is forced into the drainage system of the road. These waters come with sediments such as silt, rock debris, and suspended materials which cause different levels of inconveniences. Silt that come in the water settles at the bottoms of storm water drainage and other drainage channels such as culverts and so on. Where this is combined with rocks and other suspended debris, they may cause clogging of these channels. This poses a great danger to the carriageway and other sections of the road since flooding may occur and damage caused to important elements of such a road network. This may render the roads impassable or in extreme cases the roads may be washed away with waters. So that these effects are prevented, proper ways of preventing soil erosion along the road should be used. Planting of trees and maintenance of a healthy grass verge shall be done to ensure the soil is covered and erosion reduced significantly. This maintenance activity shall be done after inspections which are carried out indicate poorly maintained grass. Where there is no plantation grass seeding shall be used and trees provided to ensure the ground is firm enough to reduce erosion. This will provide an efficient transport network is maintained in all the seasons both wet and dry periods.

Vegetation Control

After long periods of time, shrubs and trees which exist along the road will overgrow and proper maintenance should be undertaken to ensure safety of the road users. Tress and shrubs usually pose danger to the users by causing visibility problems which may lead to accidents which could have been prevented easily. This may also cause the reduction of the drainage system effectiveness and stability of slopes. Vegetation control is therefore the most important activity that that should be employed in such cases so that safety is guaranteed to all users. The three ways in which this type of control can be administered are by use of chemical, mechanical, and manual techniques. The control technique that is used will depend on a number of factors such as the location, and the characteristics of the vegetation. When chemical techniques are used, adequate care should be taken to ensure that only the target vegetation is eliminated. A good maintenance plan is expected to improve the safety of the motorists, pedestrians, and animals using the road. Wild growth of vegetation should be prevented as much as possible. Below are the types of vegetation along the main road and the best way to provide maintenance practices.

Grass verge cutting

The grass planted along the road sides shall be maintained regularly depending on the growth rates so as to maintain the visibility to road users including motorists and pedestrians. This will also make it possible to maintain cleanliness on the grass verge since it becomes possible to pick litter from the grass. Since the proposed Murra Murra roads mainly exist in the rural areas, the grass verge shall be categorized as rural. In that case therefore, maintenance cutting of the grass verge shall be done only twice in one year. Near urban centers however, the grass verge should be cut five times in a year to ensure there is maximum visibility in such regions. The height of the grass after the cut should have an average height of 40 mm and all the cut grass is not removed. Cut grass is left on the grass verge but not collected and carried away. Other maintenance practices which will be initiated by the supervisor include; top soiling, edge trimming, and seeding. Maintenance of grass verges is economical and the overall benefits of visibility and appearance are enjoyed by the road users and the rural community as a whole.

Hedge maintenance

Where hedges exist appropriate maintenance measures shall be put in place to ensure that an attractive appearance is obtained. All the hedges that occur along the road shall be maintained by cutting and trimming them as it is appropriate. The hedges shall be trimmed once every year where the sides facing the road need to be trimmed. The vertical heights of hedges may also be trimmed or left to grow above 5 m high depending on the requirements. The cutting and trimming of the hedges will ensure that visibility on the road is maintained and at the same time open up the road for its users. This activity also ensures that the hedges do not overgrow thereby increasing the health and safety of the hedges which consequently leads to formation of an attractive environment. Depending on the growth conditions the hedges are exposed to at certain time, cutting and trimming may be done more than once every year.

Tree management

Inspection of trees that have grown along the roads shall be carried out at regular intervals to identify the ones which are overgrown. Trees that shall have grown beyond the standard accepted such that they start causing visibility for road users shall be maintained through appropriate means. According to the effects and risks that such trees may pose, pruning to reduce the branches and cutting down of trees shall be done. This will provide a clear carriageway for pedestrians and vehicles and maintain the pleasing appearance created by the trees in the areas they have grown. The health and safety of the trees shall also be assessed by inspecting them during the dormant and growing season. The assessment shall also be used to identify any possibilities of work that shall be essential in ensuring the trees grow healthy and in an attractive manner. This works shall be carried out by contractors but on behalf of the council. The overall results of providing good maintenance services on the trees is safety due to improved of visibility and an attractive appearance (“Roads Maintenance Plan,” 2008).

Hedge and tree cutting notices

Before any activity such as cutting of overgrown trees and hedges is undertaken, the public shall be provided with notices earlier enough to ensure that various problems are avoided. This will ensure that all possible dangers and obstruction to the movement of vehicles and pedestrians are avoided. This will enable the motorists and pedestrians to plan their movement early enough since they will have understood the possible consequences of such activities to their daily programs. However, all people owning private land adjacent to the road reserve shall be responsible for maintaining their trees, hedges, and shrubs according to the rules and expectations of the council. According to their condition, size, location, and effect on road visibility, the council shall decide the occasions when tree cutting and trimming shall be critical to reduce dangers. This way, the road users will have a safer time on the road.

Conclusion

The upgrade of the Murra Murra road will have an overall positive effect on the rural areas since the tarmac road will form a major connecting line between these areas and already developed towns and city. Rural development will then follow considering that more people from the modern towns will have a major destination in the Bendee Downs Eco-tourism site. Therefore maximization of this road in terms of tourism movement will trigger all the development thereby benefiting the local population.

Appendix

Reference List

Anonymous. (2000). Forest road Maintenance. Highways Management, 2, 7-12.

Lewis, C. (2009). Highway Maintenance Plan. Highways Management, 2, 95-138.

Potholes. (2010). Herefordshire Council. Web.

Roads Maintenance Plan. (2008). Shetland Islands Council. Web.